INHOUSE LAB EQUIPMENT

In-House Laboratory: Where Precision Meets Performance

Deep within our manufacturing facility lies the heart of our quality commitment: the In-House Vacuum Insulation Laboratory. This dedicated space is far more than a testing center; it's where our promise of "long-lasting temperature retention, enduring durability, and unwavering safety" is rigorously validated before any product reaches your hands.

Electrolytic thickness gauge

Salt spray corrosion test chamber

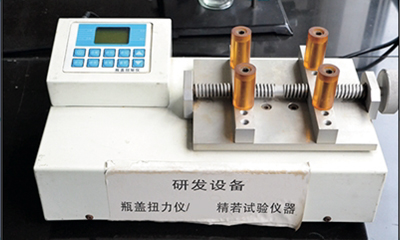

Bottle cap torque tester

Dish-washing machine

Specular chromaticity meter

Portable X-ray fluorescence spectrometer

Equipped with industry-leading precision instruments, our laboratory simulates a wide range of real-world conditions, conducting systematic scientific verification on every batch of raw materials, components, and finished products:

Thermal Efficiency Testing: In precisely controlled environments, we continuously monitor the temperature curve of our bottles and mugs over extended periods, ensuring their insulation performance consistently exceeds industry benchmarks.

Seal & Leakage Testing:

Through simulations involving pressure, tilt, and vibration, we scrutinize the integrity of the seal between the lid and the body, eliminating any possibility of leakage.

Material Safety & Durability Testing:

We employ specialized equipment to analyze the safety of all materials, including the inner liner and plastic components. A battery of physical tests—drop, abrasion, and lifespan fatigue tests—guarantees our products can withstand the test of time and daily use.

User Experience Verification:

We meticulously evaluate ergonomic details such as drinking spout design, lid operation feel, and ease of cleaning, constantly refining comfort and convenience.

This in-house laboratory acts as the ultimate guardian of our product quality. It ensures that every bottle leaving our factory is not just a container, but a reliable companion for daily life. We believe that the visible excellence in performance is rooted in these invisible depths of meticulous scrutiny.

Get the latest price? We'll respond as soon as possible(within 12 hours)