How To Make A Stainless Steel Bottle Mold ?

2023-11-03 18:00

To make a stainless steel bottle mold, you will need specialized equipment and knowledge of mold-making processes. Here is a general outline of the steps involved:

1.Design the mold:Determine the shape and dimensions of the Insulated water bottles mold. You can use computer-aided design (CAD) software to create a 3D model of the mold.

2. Select the stainless steel material: Choose a suitable grade of stainless steel for the mold. Stainless steel alloys such as 304 or 316 are commonly used due to their corrosion resistance and durability.

3. Prepare the mold pattern: Create a pattern or model of the stainless steel water bottles mold. This can be made from various materials like wood, plastic, or wax. The pattern should match the desired shape and size of the final bottle.

4. Make a mold core: If the metal water bottles has internal features or cavities, you may need to create a mold core to form those internal structures.

This core can be made using materials such as sand or resin.

5. Construct the mold: Use the pattern and mold core to create the mold cavity. The cavity will be the negative space where the molten stainless steel will be poured to form the bottle. The mold cavity can be made by several methods, including sand casting, investment casting, or CNC machining.

6. Polish and finish the mold: Once the mold is constructed, it should be polished and finished to ensure a smooth surface finish on the final product. This may involve grinding, sanding, and polishing the mold surfaces.

7. Test the mold:Before using the mold for production, it's important to test its functionality. This can be done by pouring molten stainless steel into the mold and evaluating the resulting bottle for any defects, such as surface imperfections, dimensional inaccuracies, or structural weaknesses.

8. Make any necessary adjustments:If any issues are identified during the testing phase, modifications may be required to the mold design or construction. This could involve refining the mold surface, adjusting the dimensions, or altering the mold cooling system.

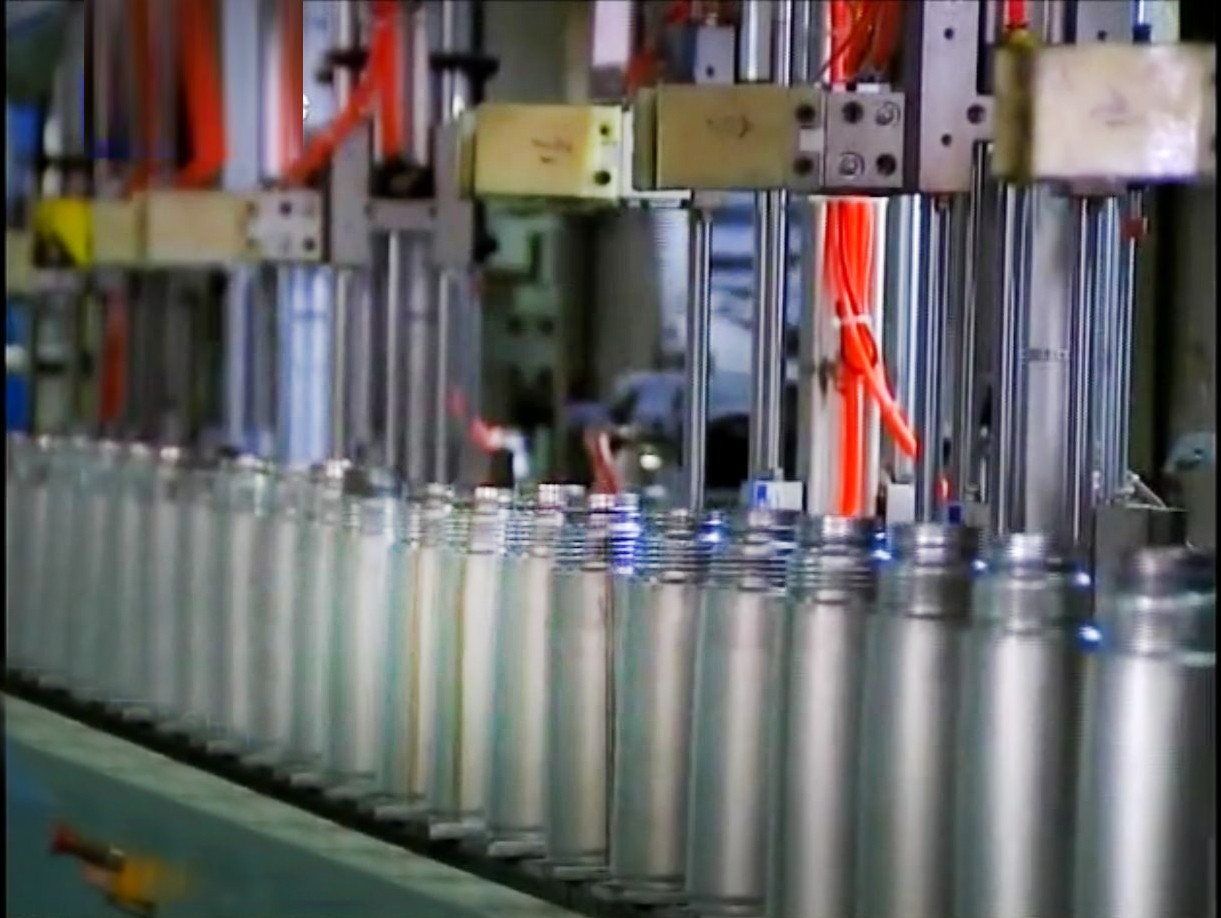

9. Production: Once the mold has been successfully tested and refined, it can be used for mass production of thermos bottle. Molten stainless steel is poured into the mold, allowed to cool and solidify, and then the mold is opened to remove the finished bottles.

It's important to note that creating a insulated sport water bottles mold is a complex process that requires specialized knowledge and equipment. It is recommended to consult with professionals or experienced mold makers to ensure the best results.

Get the latest price? We'll respond as soon as possible(within 12 hours)